In daily life, injection materials can be seen everywhere. They are described with a jumble of acronyms like ABS, PE, PP, PVC, PA, PC, POM, and PS. Each type of material has different characteristics and, therefore, the use cases of the materials is very important. In this article, we'll discuss different types of injection molding materials.

1. Acrylonitrile-butadiene-styrene (ABS)

Material properties:

Good comprehensive performance, high impact toughness, mechanical strength, stable size, good chemical resistance; Good electrical performance; Easy to be shaped and machined, it can be made into two-color molded parts with chrome plated surface.

Material application:

Suitable for making general mechanical parts, wear-resistant parts, transmission parts, and telecom structural parts.

2. Polyethylene (PE)

Material properties:

Corrosion resistance, excellent electrical insulation, chlorination, irradiation modification, glass fiber reinforcement;

High-density polyethylene (HDPE) has a high melting point, rigidity, hardness and strength, low water absorption, outstanding electrical properties, and good radiation resistance.

Low-density polyethylene (LDPE) has good flexibility, elongation, impact strength, and transparency.

Material application:

HDPE is suitable for making corrosion-resistant parts and insulating parts.

LDPE is suitable for making films, etc.

3. Polypropylene (PP)

Material properties:

The strength, hardness, rigidity, and heat resistance are better than that of HDPE, can be used in around 100 ° C. PP has excellent corrosion resistance, high-frequency insulation, and is not affected by humidity. However, under very low temperatures, it becomes brittle and isn't very wear-resistant and can age quickly

Material application:

Suitable for making general mechanical parts, corrosion-resistant parts, and insulating parts.

4. Polyvinyl Chloride (PVC)

PVC materials include hard PVC and soft PVC with the following properties:

RPVC properties:

High mechanical strength, excellent electrical performance, strong acid and alkali resistance, good chemical stability, but a low softening point.

RPVC Application:

Suitable for manufacturing rod, pipe, plate, oil pipe, and acid-resistant parts.

SRPVC properties:

High elongation rate, lower mechanical strength, corrosion resistance and electrical insulation than RPVC, and easy to aging.

SRPVC application:

Suitable for making a thin sheet, thin film, wire and cable insulation, sealing parts, etc.

5. Polyamide (PA)

Polyamide, also known as nylon, contains many derivatives and its material properties are as follows:

Material properties:

Tough, wear-resistant, fatigue resistant, oil resistant, water resistant, mold resistant, but water absorbent;

PA6 has good elasticity, high impact strength

PA66 has high strength and good abrasion resistance.

PA610 is similar to

PA1010 is translucent, less absorbent and better cold resistance.

Material application: suitable for making general mechanical parts, anti-friction parts, driving part, and chemical electrical instrument parts.

6. Polycarbonate (PC)

6. Polycarbonate (PC)

Material properties:

Outstanding impact strength, high elastic modulus and dimensional stability; Colorless and transparent, good colorability, higher heat resistance than nylon PA and POM, better resistance to creep and electrical insulation, good resistance to corrosion and wear. PC does not resist alkali, ketone, amine, aromatic hydrocarbon. It is prone to stress cracking, hydrolysis at high temperature and poor solubility with other resins.

Material application:

Suitable for making small instrument parts, insulating transparent parts and impact resistant parts.

7.Polyoxymethylene (POM)

7.Polyoxymethylene (POM)

Material properties:

Good comprehensive property. High strength, stiffness, impact resistance, fatigue resistance, good creep performance.Good wear resistance, low water absorption, good dimensional stability, but poor thermal stability, easy to burn, long-term exposure in the atmosphere aging.

Material application:

Suitable for making anti-friction parts, driving parts, chemical containers, and instrument enclosure.

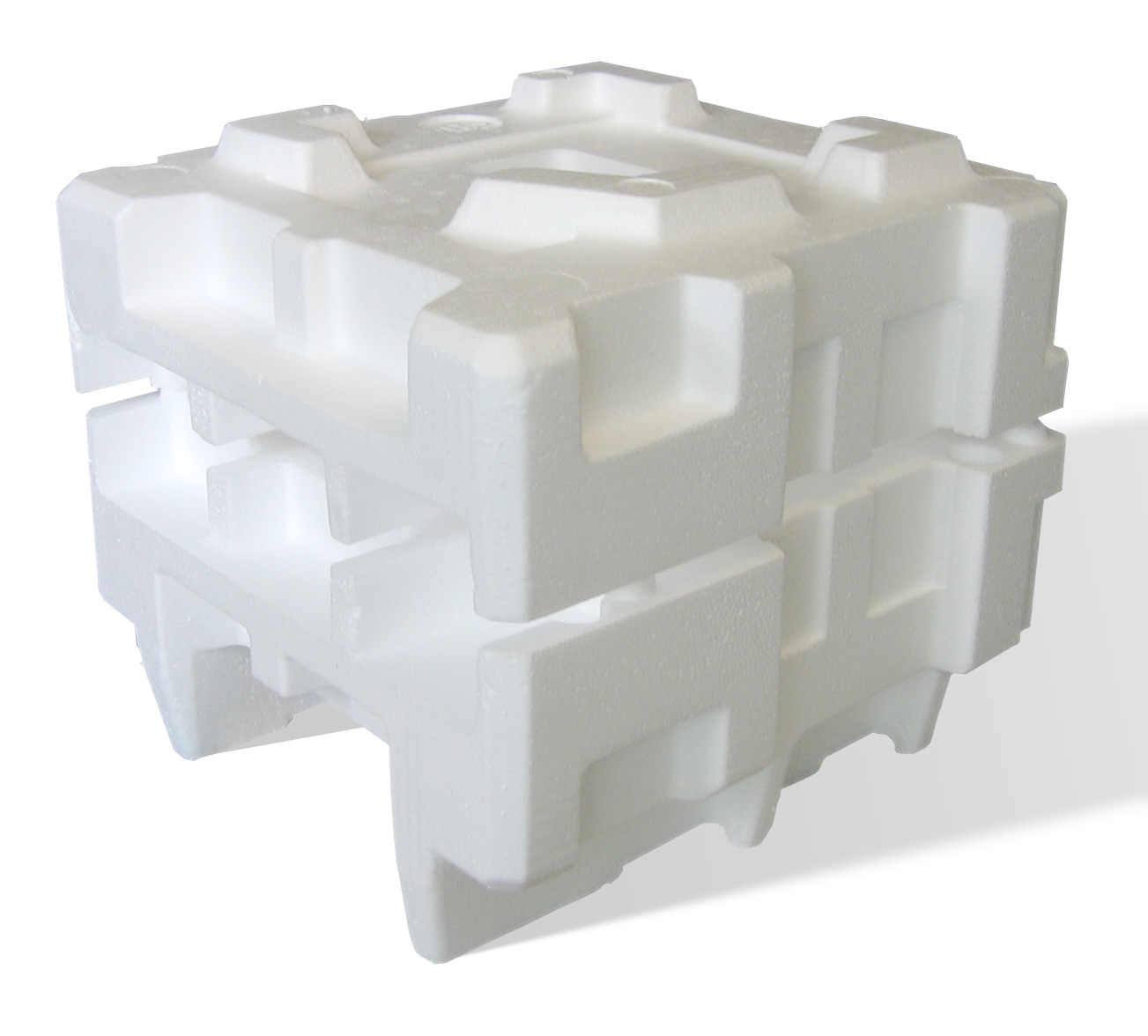

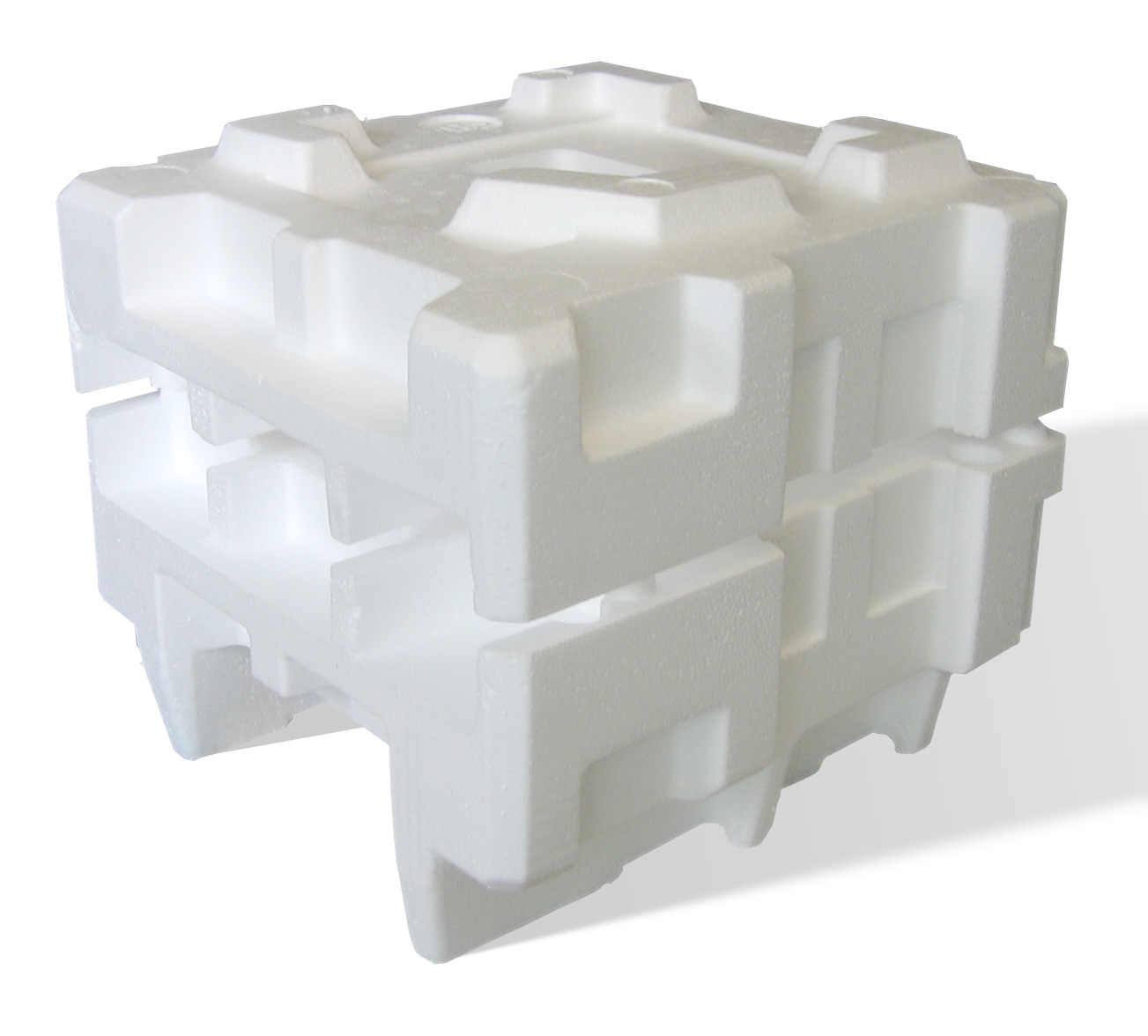

8.Polystyrene (PS)

8.Polystyrene (PS)

Material properties:

Excellent electrical insulation (especially high-frequency insulation), colorless and transparent, the light transmittance is second only to organic glass, good colorability, water resistance, and chemical stability. Normal mechanical strength. But brittle, easy to produce stress fracture, benzene, gasoline, and other organic solvents.

Material application:

Suitable for making insulating transparent parts, decorative parts and chemical apparatus and optical instruments etc.

Posted by Bo Li

Bo breaks down complex projects into turnkey-able parts. Educated in Optical Engineering, he is actually a veteran in plastic manufacturing.