Capacitors are usually indicated by symbols such as C, CN, EC, TC, PC, BC with numbers appended to them to designate their characteristics. Different types of capacitors have different circuit symbols; EC23, EC30, and EC31 are electrolytic capacitors while C162, C165, C158, and C179 are non-polar capacitors. Generally, the capacity to withstand the voltage of the capacitor is indicated next to the symbol of the capacitor circuit.

(To read our article on chip resistors, click here )1. Capacitor classification

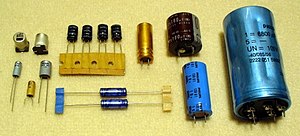

Capacitors are different according to the classification principle. There are many ways to divide them. There are mainly the following methods:

-

According to the structure, it can be divided into fixed capacitor (capacitance capacity is not fixed) and a variable capacitor (capacitor capacity can be adjusted)

-

According to the medium, it can be divided into air dielectric capacitors, solid medium (ceramic, polyester, etc.) capacitors, and electrolytic capacitors. Electrolytic capacitors are generally used as bulk capacitors.

-

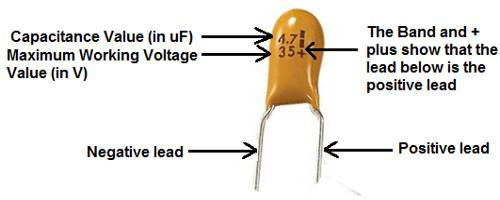

According to the presence or absence of polarity, it is divided into non-polarity capacitors and polar capacitors (such as electrolytic capacitors). Generally, the negative side of the electrolytic capacitor is indicated by "-" on the side of the cylinder. Of course, the electrolytic capacitors also have polarity, such as for audio frequency dividing circuit and motor starting. Aluminum electrolytic capacitors are for circuits.

-

According to the capacitor dielectric material: aluminum electrolytic capacitors, tantalum electrolytic capacitors, ceramic capacitors, polyester capacitors, paper dielectric capacitors, etc.

2. Some common capacitors

2.1. Aluminum electrolytic capacitor

2.1. Aluminum electrolytic capacitor

Aluminum electrolytic capacitor is made of an aluminum cylinder as a negative electrode, which is filled with a liquid electrolyte that is inserted into a bent aluminum strip as a positive electrode. It is also subjected to DC voltage treatment to form an oxide film on the positive electrode sheet as a medium. Aluminum electrolytic capacitors are characterized by a large capacity with positive and negative polarity, but they can have large leakages and poor stability. They are suitable for power supply filtering or low frequency circuits. When used, the positive and negative poles cannot be reversed.

Non-liquid capacitors of this family are called solid aluminum electrolytic capacitors. The biggest difference between them and ordinary capacitors (ie, liquid aluminum electrolytic capacitors) is that different dielectric materials are used. The liquid aluminum capacitor dielectric material is the electrolyte, while the solid capacitor dielectric material is the conductive polymer.

Why choose one over the other? Liquid capacitors, while in the long-term use on the main board, can overheat causing the electrolyte to expand due to the heat, and the capacitor to lose its function due to the expansion beyond its boiling point. If the main board is not energized for a long period of time, the electrolyte easily forms with the alumina. A chemical reaction then causes an explosion when it is turned on or when it is energized.

If solid capacitors are used, however, there is no such hidden danger. Since the solid capacitor uses a conductive polymer product as a dielectric material, the material does not interact with the aluminum oxide, and does not explode after being energized. At the same time, it is a solid product, so naturally, there is no crack due to thermal expansion. Therefore, solid capacitors have superior characteristics of environmental protection, low impedance, high and low temperature stability, high ripple resistance and high reliability.

They are the highest-end products in the electrolytic capacitor market. Solid-state capacitors are far superior to liquid aluminum capacitors in that they can withstand temperatures up to 260 degrees Celsius with good conductivity, good frequency characteristics, and better longevity. They are suitable for low-voltage, high-current applications and are mainly used in digital products such as thin DVDs. Projectors, computers, etc.

2.2. Tantalum electrolytic capacitor

Tantalum electrolytic capacitors are made of metal tantalum or niobium as a positive electrode, diluted with sulfuric acid or the like as a negative electrode and made of an oxide film medium formed on the surface of the positive electrode. This utility model has the advantages of small volume, large capacity, stable performance, long service life, large insulation resistance and good temperature performance. These are used in equipments with high-performance requirements. Currently, many tantalum electrolytic capacitors are mounted adjacent to a chip and the outer casing is generally encapsulated by a resin.

2.3. Ceramic capacitor

Ceramic capacitors are made of ceramic as a medium with a silver layer sprayed on both sides of the ceramic substrate. It is then fired into a silver film as a plate. The characteristics of the ceramic capacitor are that they have a small size, good heat resistance, low loss, and high insulation resistance. The downside is that they have a small capacity. These are more suitable for high-frequency circuits. Ceramic chip capacitors have a large capacity, but large loss and temperature coefficient, so these are more suitable for lfrequency circuits.

Trying to manage your SMT production?

NexPCB might be able to help.

At NexPCB, we have the necessary technologies and expertise for your SMT, PCB and PCBA production. We specialize in Quick-Turn prototype PCB assembly, small quantities production PCB assembly with surface-mount (SMT), through-hole (THT), and mix components. Learn more about our capabilities here

We also have a dedicated procurement team who will make sure you get the components you need at reasonable and optimized prices.

In everything, we will make sure to produce the best quality product for you by full inspection.

Just click the button below to tell us your project needs and our team would be glad to assist you!

To learn more about SMT materials check out the links below

- The Guide to SMT Material Packaging: Chip Resistor

- The Guide to SMT Material Package Type: Standard Parts

For more articles on SMT soldering, techniques and red glue, check out the links below

A Quick Primer on SMT Solder PasteBasics of SMT Solder Paste Printing

SMT Reflow Soldering Temperature Curve

What is SMT Nitrogen reflow soldering?

Basics of SMT Reflow Soldering Temperature Plate

What is an SMT Solder Paste Injection System

SMT BGA Solder Joint Slice Analysis

How to use SMT Red Glue

Posted by Liang Guo

Liang is a skillful Electronics Engineer with an ability to solder almost anything. By anything, we mean 15+ year old shattered HDD Circuitry to retro gaming consoles .